Sales Tank

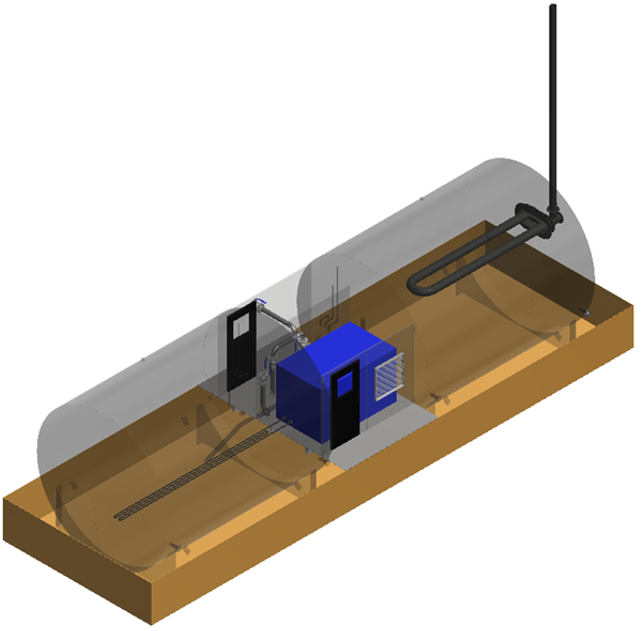

2-Part Operations Center

Containment

Knockout Tank

Operations

Power Center

Houses any piece of equipment that utilizes combustion

Full opening doors for ease of Engine Replacement

Ops Center

Houses all Test Taps, Valves and Scada Sensors

Man Door with Fluid Hauler access codes

All Valves behind locked doors

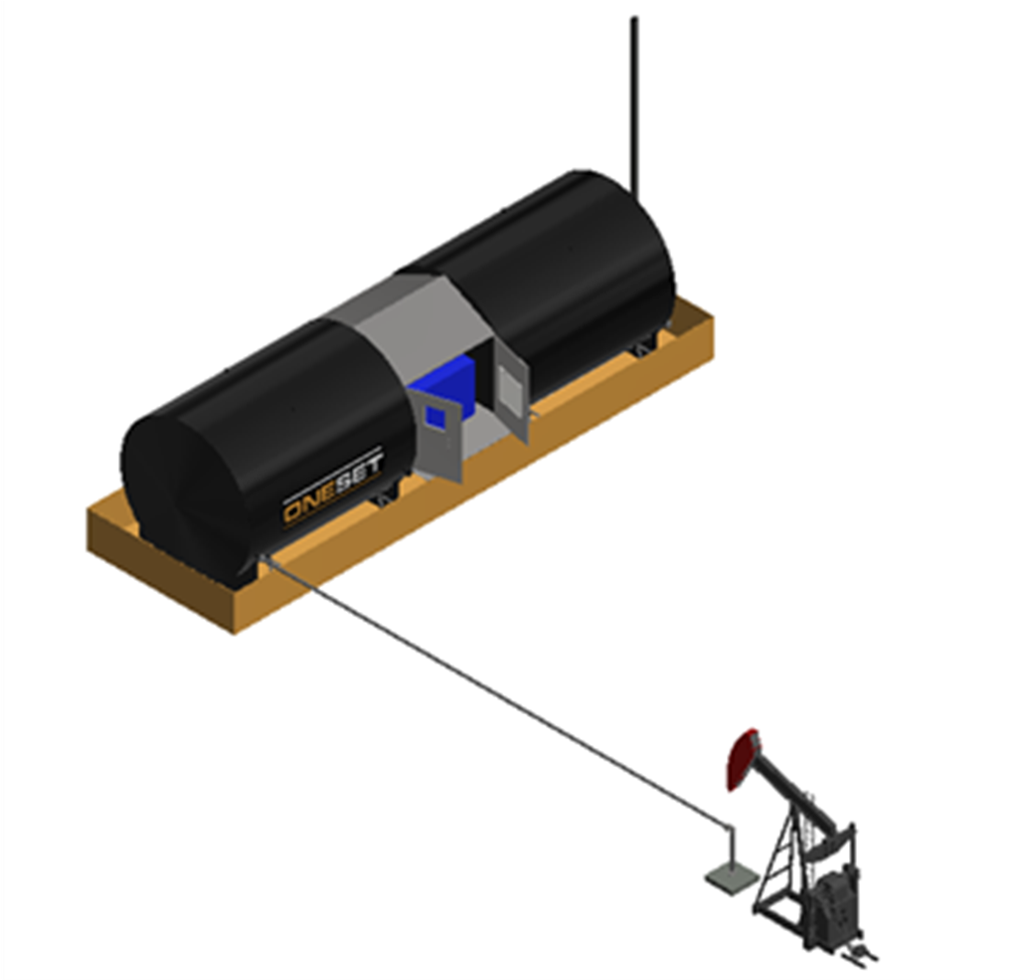

One Set | Set Up | One Crew | One Day

Two Stage – Production Treater

1st Stage – Knockout Vessel

Knock out Free Water and Solids

Warm Water (50 – 80°C) Bath to heat up well fluid on Inlet and knockout free water and solids

Heat Water with either Heat Transfer off Engine or Burner Tube to eliminate excess gas.

2nd Stage – Polishing Vessel

Burner heats oil to 80°C

Demulsifier breaks any emulsions

Oil leaves site pipeline spec

OneSet 1,000 treats 750 bbls/day (120m³) to pipeline spec

High Gas Vent

Capture All Well Gas

Vent all gas into the Polishing Vessel.

Capture all breakout gas from oil.

LPV’s– 15 psi max pressure

Run Engine and Polishing Burner off the Volume Vessel as needed.

Burn Excess Gas

If Pressure Builds above 7 psi working Pressure – Knockout Vessel Burner Fires

Burns excess Gas – Shuts off once working pressure is achieved <5 psi.

Knockout Burner is in Water Leg – heating up water and oil with excess gas.

Low Gas Vent

1

Intermittent Venting

Gas Volume Tank – Both Tanks hold 15 psi pressure – volume tank for vented gas.

2

Vapor Recovery off Tanks

Capture gas venting from oil with a VRU system to maximize amount of useable gas.

3

Utilize Engine Heat

Use Heat Exchanger off engine to heat the Knockout Tank.

Inventory

Make your Boneyard Extinct

One Piece Tracking

Eliminate Junk Parts

Scada, Burners, Chem Tanks, Chem Pumps, Piping, Valves and Security Cameras are permanent on OneSet.

Eliminate Set up Sunk Costs

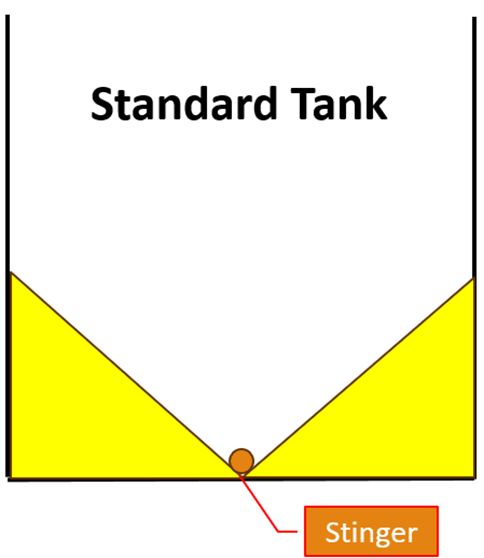

Solids Removal

Efficient Tank Stinging

Tank Shape makes sand removal easy and efficient.

Gravity feeds sand to the bottom and middle of tank

Standard Tank leaves Sand behind – can only get it with a door pull

Easy Door Pulling

Water cannon pushes sand from one end of tank towards the sting valve at the other end.

Sand and fluid naturally flow to sting valve.

Security

2 Cameras covers Entire Lease

Separate Entrances for Ops and Power Centre

Security Cameras mounted above both man doors

Camera Placement will Monitor Flowline and Wellhead

All Equipment Behind Locked Doors

All Valves, connections and Site Equipment Behind Locked Doors

Cold Weather

Eliminate Cold Weather Failures

Scada Installed in Central Location

All Scada Sensors are a short distance from panel

All Scada Sensors inside Warm Ops Centre

Scada Moves with Tank – Never needs to be dismantled

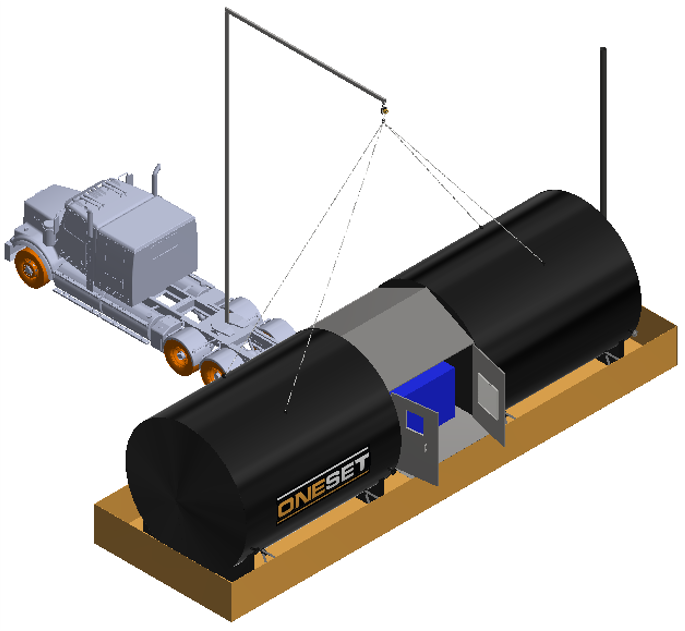

Tear Down

Disconnect

Door Pull

Move

Models

ONESET 1,000

$195,000

- 2 – 500 bbl Tanks rated to 15 psi

- Treat Oil at 750 bbls/day (120 m³/day) to pipeline spec

- Would need to haul a load of fluid out of OneSet every 6 hours at 120m³/day.

- 18’ Wide, 52’ Long – Containment walls 4’ High (667 bbls capacity)

- 2 – Tanks 14’ Diameter, 18’ long

- Power Center – 10’ wide, 9’ long

- Operations Center – 10’ wide, 5’ long

- 2 Pilots to move, 45 Tonne Picker – no Electrical Permit

ONESET 2,500

$425,000

- 2 – 1,250 bbl low pressure vessels

- Treat Oil at 1,900 bbls/day (300 m³/day) to pipeline spec

- Trucking Volume restraint of 1,250 bbl/day (200 m³/day)

- 24’ Wide, 52’ Long – Containment walls 6’ High

- 2 – LPV’s 22’ Diameter, 18’ long

- Power Center – 10’ wide, 14’ long

- Operations Center – 10’ wide, 6’ long

- 2 Pilots to move, 2 – 45 Tonne Pickers – no Electrical Permit

Contact Us